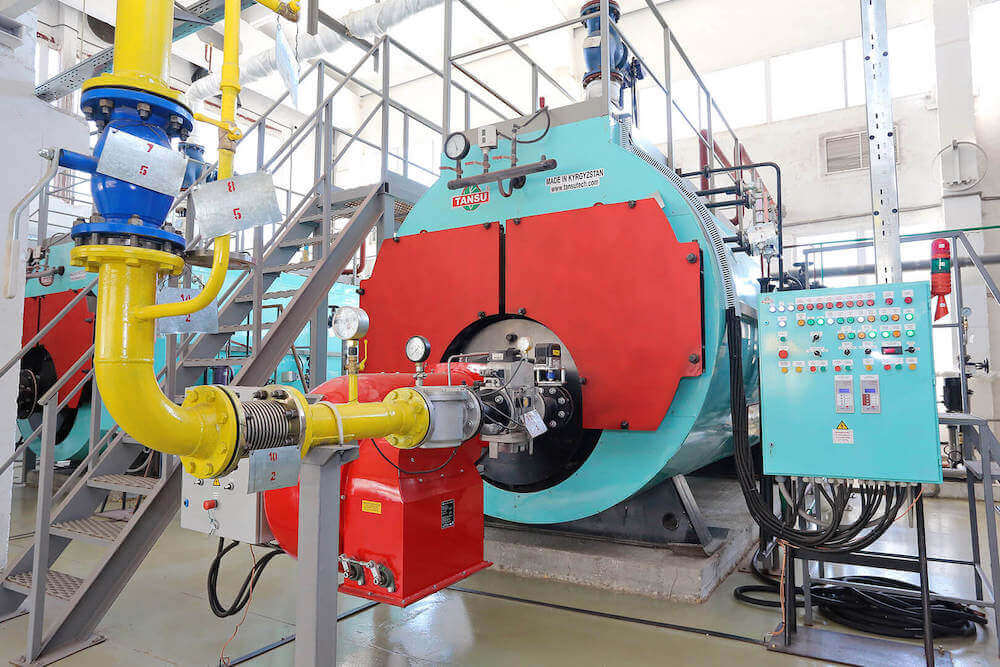

Steam boilers for industry are in high demand. They are designed to produce steam in a certain quantity and also combine the function of heating liquids for production needs. Gas-fired steam boilers are modern technological solutions, which are presented in the form of an automatic unit. The equipment is characterized by high capacity and productivity.

Choosing a steam boiler is not an easy task. In this case, it is very important to take into account a wide range of parameters: dimensions, capacity, as well as the type of fuel used. It is necessary to study all the solutions on the market to find the best option. Saving on special equipment is undesirable. It must be of high quality and of good quality. Priority is given to supplies from known and trusted manufacturers of equipment.

Industrial steam boilers TANSU can be divided into several types:

- Installations designed only for steam generation. They are used for technical purposes;

- Installations for steam production, in order to ensure the operation of steam turbines;

- Equipment for heating of work or production rooms.

If we start from the design index, steam generators can be divided into:

Horizontal. This type of steam generator is designed to provide steam for production facilities of considerable size. It stands out for its productivity. Horizontal devices are rather complicated. They are equipped with automation and safety systems;

Vertical. Such devices often take into consideration specifics of production. They are characterized by simplicity in terms of application, high safety threshold and relatively modest size. Weight of the represented installations is also relatively small.

In addition, steam boilers can be divided by the indicator of the fuel that they need. The devices can be:

- On liquid fuel;

- Solid fuel;

- Gas;

- Electric.

Each option has its own advantages and disadvantages. Industrial steam boilers on gas can be called one of the most popular options.

Leave a Reply